Manufacturing of equipment Mass Production

ATOM CO., Ltd. View Company Info

ATOM Co., Ltd. is a company specializing in factory automation, and has vast experience in the automation of the production of various industrial goods. Yasutaka Ichinose, President of the company, is confident that anything from combining the ingredients of snacks to the packaging of contact lenses can be automated. “There is no such thing as production that can’t be automated,” says Mr. Ichinose. Armed with their know-how of an integrated approach to industrial equipment encompassing everything from design to installing, the high level of technology and quality Japan is known for, and detailed customer support, the company has been receiving an increasing amount of orders from overseas and has developed into a company to look out for.

Manufacture Your Current Products through Automated Mass Production

ATOM Co., Ltd. is a company specializing in factory automation, and has vast experience in the automation of the production of various industrial goods. Yasutaka Ichinose, President of the company, is confident that anything from combining the ingredients of snacks to the packaging of contact lenses can be automated. “There is no such thing as production that can’t be automated,” says Mr. Ichinose. Armed with their know-how of an integrated approach to industrial equipment encompassing everything from design to installing, the high level of technology and quality Japan is known for, and detailed customer support, the company has been receiving an increasing amount of orders from overseas and has developed into a company to look out for.

Manufacturing Without the Word “NO”

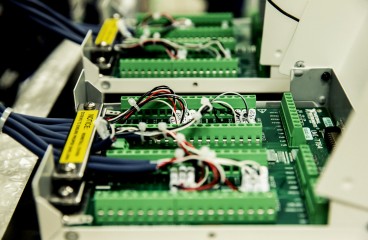

“Automation through machines will result in the capability to produce products of a consistent quality day or night. There is no longer any need to worry about rising personnel expenses or the lack of manpower. Our mission is to realize our clients’ wish to implement automated manufacturing.” Factory automation is a process that assigns tasks completed by humans in a production line to machines working automatically. This allows for higher quality and the possibility of mass production, and brings profits to clients by lowering their personnel costs. ATOM does everything: designing, manufacturing machines, and installation of equipment at work sites, all in an integrated process in-house.

“As long as we can see the product that needs to be manufactured, we can start consulting from scratch, and are able to propose a process that will result in the completion of the necessary tasks. We can automate various production lines, and implementation is a question of cost effectiveness,” says Mr. Ichinose. The company has overseen automation in various production areas such as liquid crystal and semiconductors, medical equipment, office automation, information and communications devices, testing and measurement equipment, automobiles, and food products. “No” is not a word ATOM is familiar with. No order, regardless of difficulty, is ever rejected; and with the strong will and perseverance of a samurai, the ATOM style is to work very closely with clients to make automation a reality.

The Long and Winding Road From Assembling Mass-Produced Products to Factory Automation

At the time of its establishment in 1981, the main business of ATOM was to assemble mass-produced products such as the car audio products ordered from the Japanese home appliance titan, Panasonic. At one point, the company had grown to the scale of having 1200 employees. However, domestic mass production dwindled as business moved to countries with cheaper labor costs, such as China, and the company’s business started to falter. Without the know-how of the design and development of the products themselves, ATOM faced severe times brought on by the pricing war of Globalization.

Toward the end of the 90’s, ATOM made the decision to move to factory automation, in order to survive. The company saw an opportunity for advancement in the field of factory automation, which requires a level of designing, technology and quality that is superior to the production of mass- produced products. The company started on this endeavor without much knowledge under its belt. “We started out with assembling machinery. Later, we approached machinery suppliers for repeat orders and were able to improve on our knowledge and technology. It took us ten years in order to be able to do everything from designing to installation in-house,” reflects Mr. Ichinose. From the time the decision to move to factory automation was made, ATOM has persevered through many rough patches, such as the restructuring of the company, the death of the previous president who founded the company, the Lehman shock, and the Great East Japan Earthquake. However, the company met each challenge head on and stayed strong and on course.

Solving Problems in the Production Line

Mr. Ichinose takes the voices of his clients very seriously. Designing the appropriate equipment is only possible through carefully listening to the clients’ needs, concerns, and visions. To the question of what was the most challenging order he had to deal with, Mr. Ichinose responds, “The projects that we work on always stem from frustration of the clients and are therefore challenging.”

In order to fulfill their clients’ needs, ATOM also works in the development of catenated desktop robots. These are small robots that work on a desktop, and since they are cheaper than installing a large piece of machinery, have a demand in relatively small-scale production processes. For example, a robot that applies adhesive to a section of a product falls under this category. While there are many suppliers who sell single robot units, a specification that allows for robots to work together throughout the various processes are rare, making them marketable.

ATOM puts a focus on speed, and works toward delivering products within three months when designed from scratch, and one to two months when only assembling. This stance is a natural offshoot of the mission of ATOM to solve their clients’ troubles on the production line.

Overseas Factory Automation Executed with Made in Japan Quality

ATOM recently worked on the automation of a Thai factory manufacturing automotive interior equipment. While the Thai client had been using Chinese machinery, due to frequent malfunctions as well as frustrations with bad repair services, they decided to contact ATOM in pursuit of the well-trusted, made in Japan quality. Although prices may be two to three percent higher than Chinese products, both ATOM and clients agree that considering product durability and customer service, this cost is a non-issue. April 2014 will mark the start of operations at ATOM’s third factory, opening in Kyushu in the southern area of Japan. Regarding his plans and concept, Mr. Ichinose says that machinery that is ordered will be assembled domestically in Japan and will only be delivered to the clients after passing thorough inspections and testing in order to insure made in Japan quality.

Once On Board, Stay On Board No matter how challenging the work is, employees of ATOM overcome through perseverance. This never changing belief is at the core of ATOM; a Japanese company. “This is an industry, where deliveries of products at one- hundred percent quality are very challenging. We take full responsibility of any follow up services and adjustments of our products. Once we are on board, we stay on board. This is the pride of a craftsman manufacturing in Japan. We take the voices of our customers very seriously. That is where it all begins.” ATOM will continue to offer solutions to an increasing amount of overseas businesses with problems. This samurai, even across the ocean, will stand up to any challenge with the same focus and poise demonstrated in Japan.

ATOM CO., Ltd.

Business Description: Design and development of industrial machinery and manufacturing of equipment

Headquarters Address: 358-1 Nibukata-cho, Hachioji-city, Tokyo, 193-0822 Japan

CEO: Yasutaka Ichinose

Established: 1981

Number of Employees: 46

Website: www.atom-group.co.jp