Development, design, manufacturing and distribution of industrial heaters

KAWAI CORPORATION View Company Info

KAWAI CORPORATION designs, manufactures, and distributes an array of industrial heaters. Founded in 1929 in Nagoya City, KAWAI CORPORATION got its start by producing King Seal and Hope Seal soldering irons, and for the following 80 plus years, has been focusing on the manufacturing of heaters. The company has advanced to Silicon Valley, US in 2006, mainly filling custom orders by designing and distributing heaters used in semiconductor-related manufacturing equipment. In 2007, the cartridge heaters and silicon rubber heaters received certification for UL Safety Standards. In 2013, the semiconductor gas line heater also received UL certification, and the UL Vol2 Sec.2 ASH-200 was added, allowing the company to establish its safety standards, and to form a foundation within the US.

Beyond the Scope: A Company’s Vision to the World

KAWAI CORPORATION designs, manufactures, and distributes an array of industrial heaters. Founded in 1929 in Nagoya City, KAWAI CORPORATION got its start by producing King Seal and Hope Seal soldering irons, and for the following 80 plus years, has been focusing on the manufacturing of heaters. The company has advanced to Silicon Valley, US in 2006, mainly filling custom orders by designing and distributing heaters used in semiconductor-related manufacturing equipment.

KAWAI CORPORATION designs, manufactures, and distributes an array of industrial heaters. Founded in 1929 in Nagoya City, KAWAI CORPORATION got its start by producing King Seal and Hope Seal soldering irons, and for the following 80 plus years, has been focusing on the manufacturing of heaters. The company has advanced to Silicon Valley, US in 2006, mainly filling custom orders by designing and distributing heaters used in semiconductor-related manufacturing equipment.

In 2007, the cartridge heaters and silicone rubber heaters received certification for UL Safety Standards. In 2013, the semiconductor gas line heater also received UL certification, and the UL Vol2 Sec.2 ASH-200 was added, allowing the company to  establish its safety standards, and to form a foundation within the US. We were able to speak to Motoyuki Kawai, the Engineering Manager of the North America Division, and Shintaro Hayakawa, Manager of the 2nd division of Manufacturing, who oversees manufacturing of products geared towards the US in Japan, and Yukina Nii, Sales Manager, who oversees the distribution of medical heaters.

establish its safety standards, and to form a foundation within the US. We were able to speak to Motoyuki Kawai, the Engineering Manager of the North America Division, and Shintaro Hayakawa, Manager of the 2nd division of Manufacturing, who oversees manufacturing of products geared towards the US in Japan, and Yukina Nii, Sales Manager, who oversees the distribution of medical heaters.

Breaking the Rules

From the end of the 20th century to the beginning of the 21st century, during the proactive transition of many Japanese industries moving production to China, Kawai CORPORATION also sought a partner in China, and outsourced production. In time, orders for domestic production, especially mass production, had declined. At the time, Mr. Kawai, who was working in the technology field with the opportunity to be in touch with the state of the art trends in Japanese manufacturing, saw this trend and felt the necessity to rethink what it means to be a craftsman, and to take on new challenges in order to create something new.

“For KAWAI CORPORATION at the time, the primary concern of clients was manufacturing products in a tightly controlled environment so that they looked good and were durable. However, production of items that were up to par in this sense was outsourced to China, and the problem was that no one knew what products should actually be manufactured on site in Japan. That’s when I realized that Kawai CORPORATION was a company with a structure that allowed for everything from designing, manufacturing, and sales, to be done in an integrated fashion in-house.”

Then, around 10 years ago, breaking away stylistically from many businesses in various industries, Kawai CORPORATION adopted a proposal based business style that put an emphasis on identifying and addressing needs through feedback from clients. As a result, it became apparent that there was a need for “heat” in many industries, and that this need wasn’t unique to Japan, but was a global interest.

A Japanese Company’s American Dream

In 2006, as the company was getting heavily into the proposal based business style, KAWAI CORPORATION received a call from a US-based Japanese company that was using American heaters. The call was a request to try a heater made in Japan by a Japanese business. While KAWAI CORPORATION had gained invaluable experience manufacturing many heaters customized for the specific needs of clients, ranging from household appliances to industrial equipment, this was the first order to come from the US. Mr. Kawai was determined to get an order out of this call. “I received a phone call from a Japanese-American business that was using an American heater, but wanted to switch to a Japanese made product. I thought it was a great opportunity to globalize our business, and decided that our

In 2006, as the company was getting heavily into the proposal based business style, KAWAI CORPORATION received a call from a US-based Japanese company that was using American heaters. The call was a request to try a heater made in Japan by a Japanese business. While KAWAI CORPORATION had gained invaluable experience manufacturing many heaters customized for the specific needs of clients, ranging from household appliances to industrial equipment, this was the first order to come from the US. Mr. Kawai was determined to get an order out of this call. “I received a phone call from a Japanese-American business that was using an American heater, but wanted to switch to a Japanese made product. I thought it was a great opportunity to globalize our business, and decided that our

Quality in the US

Mr. Kawai speaks of the many differences he encountered when moving to the US. “There isn’t a unified culture that all citizens share and relate to in the US. Silicon Valley in particular is a gathering place for people of a wide variety of ethnic backgrounds. Concerns and philosophies differ greatly not between companies, but between each representative. However, even in such a climate, one commonality is that changes in design happen on a higher frequency and speed.”

Mr. Kawai speaks of the many differences he encountered when moving to the US. “There isn’t a unified culture that all citizens share and relate to in the US. Silicon Valley in particular is a gathering place for people of a wide variety of ethnic backgrounds. Concerns and philosophies differ greatly not between companies, but between each representative. However, even in such a climate, one commonality is that changes in design happen on a higher frequency and speed.”

Mr. Kawai describes how the company will be able to compete in the US despite being in a land of unfamiliar methods and behaviors.

New challenge was international expansion.” Even from the design stages, many hardships that wouldn’t have been an issue for domestic business areas. “The Japanese materials were not  compatible. We couldn’t figure out how to import material from the US either. Delivery times were much shorter than we were used to in Japan. While the style in Japan was to really spend time on prototypes that were close to completion, the US uses a style that involved making prototypes while applying improvements to the product.

compatible. We couldn’t figure out how to import material from the US either. Delivery times were much shorter than we were used to in Japan. While the style in Japan was to really spend time on prototypes that were close to completion, the US uses a style that involved making prototypes while applying improvements to the product.

I felt the gap between how business was conducted in Japan and in the US.” Having a strong drive to make this first opportunity to do business with a company in the US a success, Mr. Kawai requested to be posted in America in order to conduct business at the site. “I encountered a style of business in the US where, for example, representatives would visit potential clients without extensive knowledge of heaters, to make suggestions about heating products that could be useful. This led to the revelation that this was the direction that our company had to take. Currently we have a base in Silicon Valley to expand our business by targeting US companies.”

We asked why American businesses were specifically being targeted instead of Japanese businesses based in the US. “To put it simply, it’s because America=the world. If you sell products to American businesses, those products will spread worldwide. The heaters manufactured by KAWAI CORPORATION will be used around the world. We are aiming for business beyond the US, on a global scale.” Currently, heaters by KAWAI CORPORATION are being supplied not only within Japan, but all countries where there are large semiconductor factories, such as Singapore, Germany, and the US.

“If you need the heating functions of a heater, in most cases, there is no backup for the heater, while its presence is absolutely necessary for the object to function. Despite being a very important component, the general consensus in the US is that it is better to not have heaters at all, since it is pricey, prone to malfunction, and slow in production. This is why I saw great business potential in the US.” Mr. Kawai states that Japanese products actually go very well with the current American market. The number one asset is, of course, the pride of Japanese manufacturing; quality.

“If you need the heating functions of a heater, in most cases, there is no backup for the heater, while its presence is absolutely necessary for the object to function. Despite being a very important component, the general consensus in the US is that it is better to not have heaters at all, since it is pricey, prone to malfunction, and slow in production. This is why I saw great business potential in the US.” Mr. Kawai states that Japanese products actually go very well with the current American market. The number one asset is, of course, the pride of Japanese manufacturing; quality.

“While some use the term “excessive quality,’ in the end, everyone wants a good product. The key factor is how it balances quality with the cost. Since we, as Japanese people, are supplying Japanese products, we only deliver products that meet Japanese standards of precision and quality, and we have no intent to compromise on this point.”

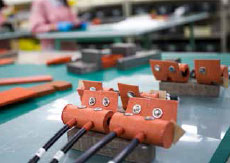

The manufacturing of the products starts from the prototyping stage in the plant in Japan, even if it is intended for American clients. “While our products are basically all custom made by hand, precision quality products are expected from us. While we can only manufacture within Japan at this point, we consider this a strength of our company.” Utilizing the time difference when manufacturing in Japan, the company is able to produce products with speeds that surprise many Americans. “At 9:00 am in the morning, when the Japanese workday starts, people are getting off work in Silicon

Valley, where it is 6:00 pm. Delivery of the daily tasks is efficient. Simple inquiries of questions or investigations of causes for issues can be addressed by the next morning. This is a speed that is hard to compete with, even in the US.” As a business that successfully advanced to the US, what are some of the strengths Japanese manufacturing processes within the American market? “It’s all about trust. There can be no misleads such as delaying delivery, or delivering products with quality that is lesser than what was agreed upon or what was expected. Placing a high value on trust is the same both in Japan and in the US.”

Valley, where it is 6:00 pm. Delivery of the daily tasks is efficient. Simple inquiries of questions or investigations of causes for issues can be addressed by the next morning. This is a speed that is hard to compete with, even in the US.” As a business that successfully advanced to the US, what are some of the strengths Japanese manufacturing processes within the American market? “It’s all about trust. There can be no misleads such as delaying delivery, or delivering products with quality that is lesser than what was agreed upon or what was expected. Placing a high value on trust is the same both in Japan and in the US.”

Coming Soon

The transparent heater, currently in development.

Breaking Standards, Building Standards

Mr. Shintaro Hayakawa is the Manager of the 2nd division of Manufacturing who supports Mr. Kawai in Silicon Valley, from the production site in Japan. In order to accommodate Mr. Kawai’s requests, the whole system and structure of the worksite was revamped. “Totally restructuring our worksite allowed us to part with our old culture and ways of doing things, and a new culture has sprouted in its place. This is why we can work with the fast pace of America. Regarding our stance with a focus on speed, between Japan and the US, we are on the same page.

Our sense of accomplishment and satisfaction when we fill Mr. Kawai’s orders become a big motivation for us.” The new system of manufacturing starts by planning in reverse from the delivery date, followed by the formulation of a work schedule, and then flexible application is made for the manpower and equipment based on individual orders. Mr. Hayakawa does all of this himself, and gives orders to each department. “I’ve adopted a method where I construct a schedule until completion, and make detailed adjustments every day by communicating with other departments such as in its design. In the past, it was rare that I would request assistance from another department, but these days, I might even ask for support from another plant.”

Lessons from Success Applied to New Frontiers

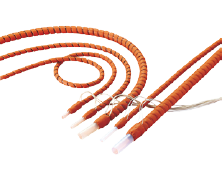

In this fashion, semiconductor related heaters helped cultivate know how pertaining to business overseas. Kawai CORPORATION is currently trying to utilize this know how and apply it to business of a different field: the medical field.

In this fashion, semiconductor related heaters helped cultivate know how pertaining to business overseas. Kawai CORPORATION is currently trying to utilize this know how and apply it to business of a different field: the medical field.

We spoke to Yukina Nii about the state of overseas expansion within the medical field.

“Actually, our products are already being used in the medical field. The most common orders are heaters for heating and retaining heat of liquids, and is often used for dialysis machines. Aside from direct heating for dialyzers, there is much demand for things like analytical equipment and cell stimulation machinery.

The company has already entered medical trade shows in Japan and has been selling itself as “Kawai CORPORATION for Medical Heaters.” Overseas expansion is in the works. “We are currently conducting inspections in preparation for entering trades shows overseas, as well as giving proposals to medical device manufacturers that are at the shows. The response has been mostly positive, and as with the semiconductor heaters, we will adopt a business style where we make pitches and proposals on heating methods that fits the needs of each individual company in order to expand internationally.”

The challenge of international expansion in the medical field is its higher quality standards. However, Ms. Nii is confident that, given its technological capabilities, this will not be an issue for Kawai CORPORATION. “Our strength of being able to produce safe, small, and lightweight products is the most important factor in the medical field. With our expansion into the medical field in sight, we also now under development new product that fulfill certain needs, such as products using clear film. We are also preparing to line up sales representatives to cover all of North America.”

We’re Shooting for the World

With the success in overseas expansion with semiconductor related heaters in mind, we asked Ms. Nii about future endeavors. “Domestically, we will place a focus on the medical and environmental fields. Internationally, we plan to apply the knowhow that was cultivated by the successful experience of our semiconductor related business to industries such as the medical equipment industry. We will especially be focusing on artificial internal  organ apparatus and assistive devices within the medical equipment market, as it is a field the US shows great prowess in, as well as being a field where we have some great achievements domestically.”

organ apparatus and assistive devices within the medical equipment market, as it is a field the US shows great prowess in, as well as being a field where we have some great achievements domestically.”

According to Mr. Hayakawa, the work site is also still going through a transitional period.

“Only a portion of our work site is capable of filling international orders. We plan on sharing our knowledge on how to deal with international orders to the entire plant. KAWAI CORPORATION will be going through some changes.”

Mr. Kawai will be aiming for the best in the world from Silicon Valley.

“In order to sustain business in the US, no matter how specific it is, you must have something that you are the best in the world at. Listening carefully to the clients and proposing the heaters that best fit their specific needs, is a business style that makes possible for growth to become No.1 in the world. You can make a heater in the US or China. What makes American clients demand for one ‘Made in Japan’ is not patented technology nor its state of the art methods. We will keep honing what is unique to us, and we will let the world know that Kawai CORPORATION products will fulfill all the ‘wishes’ that clients have towards quality.”

KAWAI CORPORATION

Headquarters: Nakahira Tenpaku-ku Nagoya-city, Aichi 468-0014 Japan

Business description: Development, design, manufacturing and distribution of industrial heaters.

President: Shinichi Saku

Established: 1929

Number of Employees: 135 Employees

Website: www.kawaidenki.co.jp/