Laser and Vacuum Casting prototype design and manufacturing

CrossEffect, Inc. View Company Info

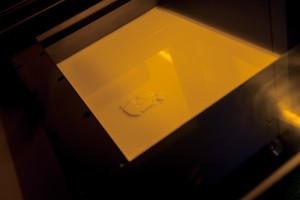

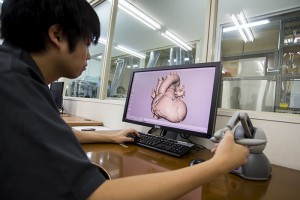

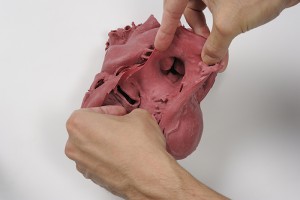

CrossEffect is known for their work developing and prototyping industrial plastic products used for items such as cell phones. Their speciality is their resin processing technology called Laser Prototyping. Boasting the “world’s fastest” prototype production speed,crossEffect supports their clients in product development. Furthermore, as the second pillar of their business, they have developed Cardio Simulators: 3D models of hearts based on CT data. Cardio Simulators are soft 3D models of hearts created, based on CT scans taken at hospitals, through the use of DICOM data, laser prototyping technology, and special molds. Not only the outer surface, but the inner cavities and affected areas are reproduced with great accuracy. It’s even possible to cut them open with a scalpel as preoperation simulators.

Laser and Vacuum Casting prototype design and manufacturing

CrossEffect is a small factory in Fushimi, Kyoto, known for their work developing and prototyping industrial plastic products used for items such as cell phones. Their specialty is their resin processing technology called Laser Prototyping. Boasting the “world’s fastest” prototype production speed, crossEffect supports their clients in product development. Furthermore, as the second pillar of their business, they have developed Cardio Simulators: 3D models of hearts based on CT data. We interviewed Managing Director Masatoshi Takeda, who upholds the idea of “Made in Kyoto, Japan,” with regard to his business development and global vision.

Aiming at the Global Arena from Start: Making a statement with “Made in Kyoto, Japan”

– Tell us about your business.

Our main business is the prototype development and production of industrial plastics, and “Rapid Prototyping” is our main strength. In terms of product development support, working alongside our clients, we do everything from designing, planning, to 3D data construction. While supporting their development, we conduct the development itself at high speed; this is our forte. The development and patent races of today are all competitions of time. What our clients require from us isn’t cost or quality, but fast service. To meet this demand, we devote our management resources to faster service, and operate under the motto of “world’s fastest.”

– I sense a special attachment to the idea of “world’s fastest.” Does your focus on “the world” stem from the local color of the city of Kyoto: a city known around the globe?

– I sense a special attachment to the idea of “world’s fastest.” Does your focus on “the world” stem from the local color of the city of Kyoto: a city known around the globe?

From the time I started this company, aiming for the global arena has always been a mission of mine. My intention has always been to conduct business globally, crossing the arbitrarily drawn borders of countries and prefectures. Currently, I represent Kyoto Shisaku [Prototype] Net, the manufacturing industry association in Kyoto. I have a deep appreciation for how wonderful our home city of Kyoto is. Both domestically and internationally, people regard Kyoto as a city of quality and sophistication. The fact that world renowned companies with roots in Kyoto don’t move their headquarters elsewhere, is also an influence. These days, we at crossEffect, also emphasize “Made in Kyoto, Japan.” We believe that accumulation of progressive innovations is the true essence of tradition. Tradition can only be born through innovation.

The Opportunity Seen by the “Mind’s Eye”: The Development of The Cardio Simulator

– Tell us about your new business, the Cardio Simulator

Cardio Simulators are soft 3D models of hearts created, based on CT scans taken at hospitals, through the use of DICOM data, laser prototyping technology, and special molds. Not only the outer surface, but the inner cavities and affected areas are reproduced with great accuracy. It’s even possible to cut them open with a scalpel as preperation simulators.

– That’s wonderful. However, I can’t see a clear link between speed conscious prototype development and Cardio Simulators. What triggered the development of Cardio Simulators?

We started to develop Cardio Simulators four years ago. Things started happening when Dr. Shiraishi, the Director of Pediatric Cardiology at the National Cardiovascular Center, contacted us. Actually, I had met him eight years ago, and was asked for cooperation in a Cardio Simulator project. However, at the time, I declined.

– After declining eight years ago, what led to your collaborations 4 years later?

In short, it’s because of my growth as a Managing Director. In a study group on Drucker, I came across his words; “managers should focus on opportunities rather than problem solving.” At the time, I was too busy dealing with problem solving that should have been taken care of by our Sales Representatives, and was incapable of dealing with the fundamental work of a Managing Director: “exploiting opportunities.” That was me eight years ago.

– Kyoto Shisaku Net, mentioned earlier, prompted you to make a change, didn’t it?

Yes. The Representative of Kyoto Shisaku Net at the time gave me a good scolding and said, “There is ‘a river of information’ in front of everybody, and opportunities are floating in the ‘river.’ Whether you can see or seize these opportunities depends on the individual. You can’t see them simply because you are looking through a ‘layman’s eye.’ Develop your ‘Mind’s eye [ability to visualize].'” I was shocked. This is when I learned what my responsibilities were as a Managing Director of a manufacturing company. In other words, my duties as a Director are to focus not on problems, but on opportunities, meet various people, use these connections to discover new opportunities, then along with the company, use this to create new business. Although it didn’t fully make sense to me at the time, after three years, I gradually started seeing the “river of information.” Then, I began to concentrate on training my staff to be my hands to grab opportunities from the river. Around that time, I met Dr. Shiraishi again. This time around, the opportunity came into focus. I happily offered my services.

– Was starting a new business project while maintaining the core business of rapid prototyping challenging?

– Was starting a new business project while maintaining the core business of rapid prototyping challenging?

For the first three years, we were offered grants from the government, and we undertook fundamental development, product development, marketing research and so on. Product development itself moves ahead with trial and error, and as long as it moves ahead, product samples can be made. What was a headache, however, was balancing this with the main business during the development phase, and towards the end of this phase, coming up with ways to get the project off the ground as a new business venture. These two issues, which really put a manager’s skill to the test, did pose a serious challenge.

The Blue Ocean Isn’t Something to Discover, but Is Something to Create

– Looking back on those days, what was the reason for your success?

In terms of technology, good engineers at small-and-medium-sized enterprises can produce almost anything with reasonable quality. Yet, I believe the reason our Cardio Simulator project is thriving, is that our mission is clear. Having a clear mission changed both our employees’ motivation and perspective on craftsmanship. Without a mission, work is nothing but a series of given tasks. I call “mission” the magic word that transforms tasks into real work.

– Is it true that, aside from the internal factor of a mission, what gave birth to the Cardio Simulator came from a managerial standpoint?

When small to medium companies start on a new business project, their lack of manpower, funds, knowledge, and experience drives them to compete in the pre-existing market known as the red ocean, in order to join a competition of costs. In reality, the blue ocean is neither something you find nor look for. You create it yourself. This led me to start new business in a completely new field.

– So instead of developing a market, you create it altogether?

– So instead of developing a market, you create it altogether?

Exactly. One thing we kept in mind as we started our advance into this new field, was to fully utilize all pre-existing factors within the company such as technology, experience, equipment, and manpower, in order to create a new market; this was the minimum. We filtered and examined many opportunities floating in the “river of information.” As a result, we concluded that in the case of our collaboration with Dr. Shiraishi, with the exception of medical expertise, we already had all of the resources necessary to launch us into a totally new field. Therefore, the Cardio Simulator is not a product of the perspective of a craftsman, but of a manager.

Global Business Expansion in the Next 10 Years

– Tell us about the future of the Cardio Simulator.

We have set our goal to develop our business to a global scale in ten years time. The CardioSimulator is one of the pillars of our world business strategy. We are going to eliminate the concept of borders between countries or regions from our thoughts. For example, when you go from Kyoto prefecture to Shiga prefecture, no one is conscious of the border being crossed. That’s how I want to move around in this world. I can’t speak English, but that hardly matters. We will prove that having a non-English-speaking director plays no part in successful overseas expansion.

– From now on, is it difficult for manufacturing industries to compete internationally without a management perspective?

This is just my personal opinion, but it would be difficult for a company to compete internationally without at least having one’s own products and services. Furthermore, I believe that it is a managerial perspective that gives birth to these strong products and services. Even now, I evaluate encounters and opportunities through the gaze of a manager in order to see if they can be acted upon utilizing only pre-existing company resources. That’s the duty of a Managing Director. As the Managing Director, I hone and improve both my own “mind’s eye” that sees evaluates opportunities floating in the “river of information,” and the “hand” to grab these opportunities: my employees.

CrossEffect, Inc.

Business Description: 3D R&D prototype model manufacturing

Headquarters address: 43 Takedawarayacho, Fushimi-ku, Kyoto City, Kyoto 612-8443

President & CEO: Masatoshi Takeda

Established: 2001

Number of Employees: 25

Website: www.xeffect.com/english/index.html

For all inquiries regarding crossEffect, Inc.,

Please contact to Mr. Paul Richardson, Marketing coordinator

Global Sales Division

Phone: +81-75-622-2600

E-mail: paul@xeffect.com