Product design and development, prototyping support

SWANY Co. Ltd. View Company Info

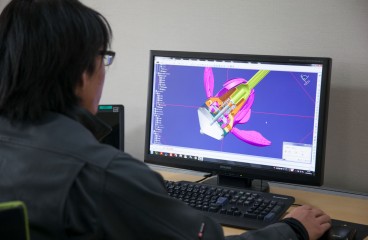

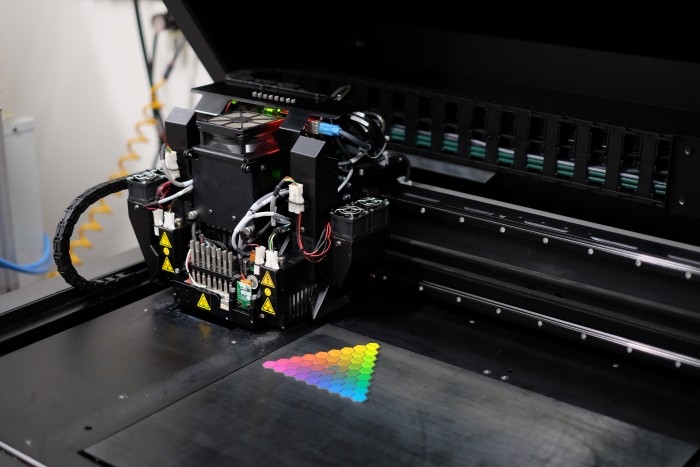

Swany Co., Ltd., is a company that makes excellent use of modeling technology in making product designs and prototypes with the use of the latest 3D printers and 3D CAD to offer consistent support of mass production. The company speedily converts the ideas of customers into data, and produces a prototype using a 3D printer. Thus, this greatly reduces the time for product development. Also, because the company can quickly deliver 3D data, it can even respond to extreme customer requests; even only with a two-dimensional drawing, or sketch, the company can “meet you in the morning, and then deliver a prototype in the evening.” The company has attracted attention with its continuous growth by making full use of 3D tools and design, together with the trust and technical capabilities associated with small and medium-sized enterprises unique in Japan.

What the customers need is, “The ability to offer solutions that exceed the customers’ expectations.”

“What the customers need is the ability to offer solutions that exceed the customers’ expectations.” There are many instances where people say, “let’s make this,” or “let’s do it this way;” however, even though there are many good ideas, they would eventually have to be given up because it is impossible to develop them in a short period of time. If there is a way to bring these ideas to life quickly by converting them into data, or to produce the actual product, then it would be great. The company’s Chief Executive Officer (CEO), Yoshihiro Hashizume, believes that by turning something that cannot be done into something tangible piece by piece, then new ideas and challenges will arise, and this will ultimately lead to the development of a superior product. “We want to be the company that works together with the customers so that they can find what they are looking for,” says Mr. Hashizume.

The 3D printer is the one that can realize this idea. Now that 3D printers are attracting attention, Hashizume immediately introduced a 3D printer since he took office as CEO. In Swany, the technicians of the company are free to use the 3D printer anytime, and this creates an environment that enhances creativity.

The world’s most advanced technology was adapted during a meeting with Stratasys

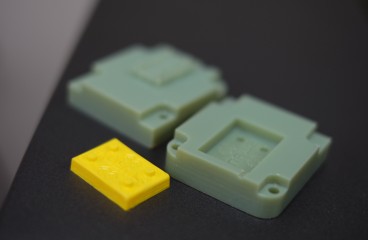

Swany introduced the 3D printer “Objet260 Connex” made by Stratasys Inc. in 2011. The machine is used to make prototypes to confirm shape and function of a product, as well as for shaping the mold used for injection molding.

The Objet260 Connex 3D printer can use a wide range of resin materials such as hard, transparent, resin-like, and even heat-resistant types; and this makes it suitable for the company’s various business needs with regard to confirmation of shape and function of product. The Objet260 Connex 3D printer is also highly regarded for its short production time and the smooth surface shape of the product. “Now, there will be many good ideas since we have created an environment where our technicians can have lots of experience by learning from their mistakes,” stat. Hashizume,. Young designers do not have much experience yet and so they are afraid to make mistakes, but with a 3D printer, “it does not matter how much you fail,” (Mr. Hashizume, CEO).

In addition, the special quality of the 3D printer that the company uses is “Digital Molding,” where molding is a combination of the metal mold base (metal mold) and a nesting mold shaped by a 3D printer; the nesting mold is made from resin (resin type). The resin material is ABS (acrylonitrile butadiene styrene) resin, and the digital mold is made by injection molding with the same resin (such as acrylic resin) as the product. These are used for low-volume manufacturing of components that are used for evaluation purposes.

For example, digital mold is used in the production of light diffusion filters that are fitted into automobile lights for evaluation. Depending on the efficiency of diffusion, light diffusion filters can halve the number of LED lamps used, and so it is essential to make prototypes. Although, there are tools to analyze the refraction index and light projection, in the end, it is important to make a prototype that is made of the same resin as the product. Using digital molds can hasten the production of prototypes that are used for evaluation, which leads to a significant reduction in the cost of producing metal molds used for mass production.

In a digital mold, the production of simple-shaped products is possible with about 50-100 shots of small-lot production; however, if there is a need to make 1,000 pieces then a metal mold is indispensable. Modifying the metal mold many times over in order to complete the mold while looking at the molded component can overshoot the budget and extend the delivery time. However, if a resin mold is made and evaluated beforehand, then the results can be adapted to the mold that is used for mass production, and this will lead to significantly reduced costs and man-hours required for modification. “Because we want to consider each shape of the parts of the metal mold, we test using a digital mold. I believe this is the correct approach.” (Hashizume).

However, digital mold is not simply fitting the resin in the mold. During molding, it is necessary to finely adjust the temperature and pressure, if there are mistakes then the mold is broken. In other words, technique and skilled craftsmanship regarding metal molds are essential. It can be said that this technology is a synergy of the fusion of the latest technology and years of craftsmanship.

SWANY Co. Ltd.

Business Description: Product design and development, prototyping support

Head office: 7361, Tomigata, Ina city, Nagano 396-0621, Japan

Chief Executive Officer: Yoshihiro Hashizume

Number of employees: 15 / Date established: 1970