Passing the tradition of Japanese wood processing to current generation

Maruoka Kogyo is Japan’s proudest maker of high-quality wooden canvas frames. By passing the old-age Japanese tradition of wood processing to the current generation and using the finest materials, the company has been making wooden canvas frames for years and its products are widely used by various famous painters and art museums in Japan. The combination of carefully-selected quality materials, skilled craftsmanship and the high precision of their manufacturing machines gave birth to a wooden canvas frame that can hold paintings even a century has passed.

The Kiso valley, an area located in Japan’s central mountains in Nagano prefecture that spreads across an area of more than 3,000 meters, has become widely known for its production of lumber since ancient times in Japan. Maruoka Kogyo operates a factory deep inside Kiso valley’s lush forests surrounded by steep mountains. Maruoka is a famous manufacturer of wooden canvas frames in Japan. It is so famous that its name has become synonymous with wooden frames.

The Kiso valley, an area located in Japan’s central mountains in Nagano prefecture that spreads across an area of more than 3,000 meters, has become widely known for its production of lumber since ancient times in Japan. Maruoka Kogyo operates a factory deep inside Kiso valley’s lush forests surrounded by steep mountains. Maruoka is a famous manufacturer of wooden canvas frames in Japan. It is so famous that its name has become synonymous with wooden frames.

As a matter of fact, Maruoka occupies approximately seventy percent of wooden frame shares in the Japanese market. In 1947, the company began as manufacturer of seiro, a wooden frame holder with reed base used to steam food over a pot, using lumber from the Japanese cypress from the Kiso valley as the main material. The company has then begun making wooden canvas frames since around 1955 and it firmly secured a position of being one of Japan’s top manufacturers after sixty years of thorough research and improvement of its processing technology.

Extreme quality products sought by Japanese craftsmanship

In a proud statement made by Mr. Hiroto Yukawa, the company president, he said, 叫Our wooden canvas frame production system is fast and very efficient that we almost think that our products possess an excessive quality for an ordinary wooden frame used for paintings. This technique is achieved by Japan’s advanced technology and no one in other countries could make such high quality wooden frames.” He added, “Judging from the measurement, precision and durability of some of the products made by other countries, it appears they have a problem in some degree. I think it is attributable to the difference of sense of craftsmanship between Japan and other countries.

This piece of wood is gold

It may be true that paintings, by themselves, hold their own intrinsic qualities and wooden frames, who act as their support, might not affect them in any way. However, we want our wooden frames to still hold paintings even 100 or 200 years have passed and we keep in mind that wooden frames should not affect paintings. Those are the reasons why we make them. When it comes to wooden frames made from high quality materials, assembled together with ingenuity and are created with high precision, Maruoka’s products are the simply the best and they beat out other products from competitors.”

The factory: merging automated production line and techniques of a skilled craftsman

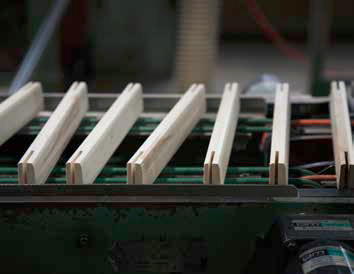

The secret behind the creation of high quality wooden frames is none other than the factory itself. From an outside perspective, Maruoka’s factory has an essence of a traditional woodworking shop. Inside the factory, the refreshing fragrance of natural wood drifts in the air and the automated modern wooden frame production line stand in rows. The main production line machines come from Weinig, a German company.

Techniques of a skilled craftsman

This is a caption text for the image

The manufacturing process such as cutting surfaces, toning, chamfering and creating miter joints are lined up in order and done in rapid succession and the finished products get transferred to the quality control area. The production of standard wooden frames is fully automated. On the other hand, made-to-order wooden frames, meeting the wishes of customers