Implant plate for animals

Kobayashi Precision Industry Co., Ltd. View Company Info Implant for small dogs

Implant for small dogs

A wide range of orders, from semiconductors to automobile industries, reach to Kobayashi Precision Industry Co.,Ltd. They work with all kinds of metals and with such fame, they have had experienced working with JAXA for the Hayabusa project, and with Nikon University to created small-breed dog implants. There is a big demand for medical equipment for animal treatment and Kobayashi Precision Industry is here to answer the needs.

At the Frontline of Animal Healthcare

Kobayashi Precision Industry is skilled in a variety of metalworking, from semiconductors, automobiles to robots, since its foundation in 1980. Kobayashi Kazumasa, President of the company, says that they are willing to answer all inquiries from all sorts of field by researching and collecting the information. As a result, they have been able to build strong relationships with many industries and attained its fame they have today.

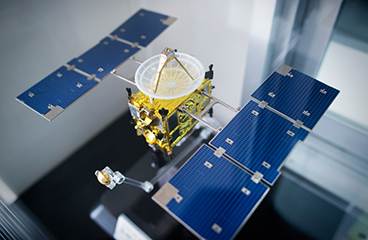

Kobayashi had a strong desire to work in the aerospace industry and was approached by JAXA (Japan Aerospace Exploration Agency) to work for the world’s first project to retrieve the samples from asteroid Itokawa. The project of disassembling the capsule ended in a great success.

Now, the company’s goal is to work for the airplane industry. They are in aim of manufacturing jet engine components using titanium and Inconel. Both are extremely difficult to shape and requires a high level of knowledge and skills to process. However, at Kobayashi, they have experience working with both of the alloys for over 20 years.

Recently, Kobayashi Precision Industry took a step further and started developing medical equipments for animal treatment. The very first product they manufactured was the small-breed dog implant. Foreign firms hold an overwhelming share in manufacturing animal implants. However, larger dogs are favored overseas while smaller dogs are popular within Japan. Thus, while there is enough medial equipment to breed larger dogs, market lacked in equipment for smaller dogs. Kobayashi saw a big potential.

He started off by visiting research institutes and firms to collect all of the information and data needed to start off business within the medical field. It was not easy to develop applications for animals, but Kobayashi was fortunate enough to encounter with a veterinarian, Professor Kazuya Edamura (Nihon University College of Bioresource Sciences), one of Japan’s few surgeons specialized in small animals. The encounter with Professor Edamura was a big turnabout for the company. Professor Edamura always had an interest in reducing cost while maintaining the quality of Made in Japan for medical equipments used for small dogs.

They conducted thorough research and insight at Nihon University veterinary clinic to find out the strengths and weakness of the existing products used. Two types of screws were used to fix the plates; cortex-screws and locking-screws. Cortex-screws are flexible which could be freely adjusted. Flexibility is essential in repositioning the bones. However, cortex-screws had a lower fixation power, resulting in a higher risk of coming loose. Thus, despite of its flexibility, veterinarians preferred using locking-screw that were much reliable and safer. However, veterinarians were requiring screws of the two characteristics combined, with high flexibility and strong fixation power. It was a challenge to attain high flexibility while providing strong fixation powers. After thousands of experiments and failures after failures, Kobayashi was able to develop a product that answered the needs in the field of animal treatment.

Introducing “MADE IN JAPAN” Quality to Animal Healthcare Industry

Large dogs are favored in America. Yet being said, there is a stable popularity of smaller dogs among the celebrities. Kobayashi Precision Industry sees a business potential in the foreign market also, for the need for small-breed dog implants. The market is competitive but Kobayashi, the president of the company, is confident to win over the market with “Made in Japan” quality. Every product is manufactured domestically, within Japan, with quality thoroughly controlled. Since these equipment are inserted into the body, titanium is used and all colorants are omitted for safety. Kobayashi Precision Industry is also reducing any unnecessary costs by hiring and using best to lower the cost, to compete with the market price.

Kobayashi Precision Industry continues to development demand-oriented products in the field of animal healthcare, and expanding their business worldwide.

Kobayashi Precision Industry Co., Ltd.

Business Description: Manufacturing precision machined components

Address: 4-1-54 Onodai Minami-ward, Sagamihara-city, Kanagawa, 252-0331 Japan

President: Masazumi Kobayashi

Founded: 1980

Number of Employees: 22

Website: www.kobasei.com/eng/