Located in Higashi Mino, Gifu Prefecture, where more than half of Japan’s ceramics are produced, Maruasa Porcelain Factory Co., Ltd. is the industry leader in manufacturing cups and saucers. All ceramics are baked at 1,300 degrees Celsius or above for 22 hours, resulting in high-endurance products. The OEM products produced by Maruasa are design unique to Japan. Customers range from major tableware manufacturers in Japan, to the United States and Asia, delivering more than 250 million items worldwide.

Companies

Introducing Beauty and Health Equipment to the World Japanese startup company, MTG Co. Ltd., is growing rapidly as it continues to develop innovative products in the field of beauty and health equipment. ReFa have already seen cumulative sales of five million units and has become a must-have item for Japanese women. Wearable training gear, SIXPAD, wearable training gear for a stronger, more beautiful body, had also became one of the popular hits for MTG. How did MTG managed to grow in such a short time. Let’s explore their success story.

Down Town Tokyo, Home for Start-up Companies Hamano Products Co., Ltd., based in the heart of down town Tokyo, is working on innovative projects utilizing its cutting edge technologies. Keiichi Hamano, CEO of Hamano Products, founded Garage Sumida, a facility for companies and research institutions to research, create prototypes and develop products, which has drawn attentions of many start up companies.

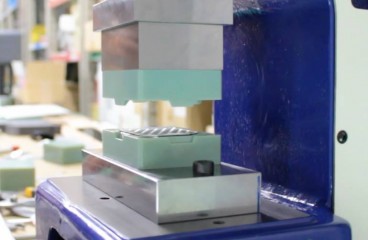

Japanese SME Fuels the Manufacturing Revolution with Digital Mold® It is quite rare to find such an innovative company in a small town of Ina, Nagano, but Swany Co. Ltd. with its cutting-edged technology, is turning the wheel of Japan’s manufacturing revolutions. Techniques of 3D molding resins and ABS plastic for injection molding allows to cut down the cost and time dramatically, and Swany is utilizes these technologies to bring out the most out of it for its customers. 3D technology is progressing faster than ever and we are seeing a big shift in the market.

Atom Seimitsu Co., Ltd., introduces AT9000 Series of linked tabletop robots. It is a revolutionary system that automatizes manufacturing processes that were previously only done by hand, allowing customers to achieve consistent quality of output. These robots are customized to perform tasks like soldering and coating which could be used autonomously or linked to other units. The units offer applications for detailed work performed in diverse industries such as automobile, semiconductor, liquid crystal display, and food.

Plus / minus 1mm. That’s the level of precision Shimano’s belt conveyors are expected to operate at for an automated production line of an automotive manufacturer. Their conveyor belts are not just a delivery system that connects production units, they quickly transport the processed products from one unit to the next, delivering them to the exact location in a highly precise manner. Because of the high precision, they are often used alongside industrial robots. Some of their fastest belts clock in at 120m per minute, which are great for large-scale factories overseas.

ATOM Co., Ltd. is a company specializing in factory automation, and has vast experience in the automation of the production of various industrial goods. Yasutaka Ichinose, President of the company, is confident that anything from combining the ingredients of snacks to the packaging of contact lenses can be automated. “There is no such thing as production that can’t be automated,” says Mr. Ichinose. Armed with their know-how of an integrated approach to industrial equipment encompassing everything from design to installing, the high level of technology and quality Japan is known for, and detailed customer support, the company has been receiving an increasing amount of orders from overseas and has developed […]

“Will this machine be operated by primarily male or female workers?” “When pushing buttons while looking at the programming screen, what are the optimal specifications of location and height of buttons, and the size of the screen?” These are some of the detailed questions that may arise in a meeting between designers of the technology department of Iwashita Industrial Co., Ltd. and clients. After the clients’ requests and views on specifications for the comfort and ease of equipment operation are collected, the designers will make proposals, revise, and make proposals again; repeating the process over and over. The resulting equipment has the finesse of an immaculately tailored custom suit. The […]