Brand new technology for stampling technology WARISAKI

Seki Press Co. Ltd. View Company Info

Seki Press Co. Ltd. has realized the new stamping technology which splits a metal like a string cheese for complex 3-D shapes.

It is a process of using a metal mold to split and tear metal materials such as iron, bronze, aluminum, stainless steel, brass, and more, that are in the form of plates, coils, and bars. It is called the Warisaki Method which we have patented. We have realized the new stamping technology for complex 3-D shapes, which could lead to cost reduction in various kinds of products.

Did you know there is a man who can split metal like string cheese in Japan?

The Warisaki Method

I hear that your company possesses a patent of a very unique, one of a kind process. Would you mind elaborating on this?

President Seki: It is a process of using a metal mold to split and tear metal materials such as iron, bronze, aluminum, stainless steel, brass, and more, that are in the form of plates, coils, and bars. It is called the Warisaki Method which we have patented.

Please tell us some of the strengths of Warisaki.

President Seki: There are two main advantages to Warisaki: improved strength and a shorter processing time. To help see these two advantages, I would like to use a 3-dimensional metal part as an example. Up until now, we had been relying on additional processing, such as soldering or welding. This method has the disadvantage of having inherently weak points where the pieces connect. Forging results in improved strength, but also leads to increased steps in the process, and the necessity of heat treatment.

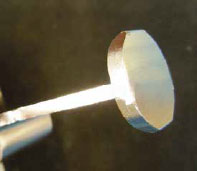

However, the Warisaki Method allows us to punch materials, creating 3D shapes with no conjoining areas. We are now also able to create complex 3D castings in a unified body by using progressive dies, something that was impossible with conventional metal presses. In such a manner, the Warisaki Method improves strength, quality, and lowers costs, all at the same time.

How does the production cost of Warisaki compared to conventional methods?

President Seki: The cost of the die itself goes up, but with the reduction of processing times and energy conservation, we can cut costs by 50%~80% compared to conventional methods. I would also like to note that, compared to conventional metal presses, the number of steps needed in production are greatly reduced, which is a major advantage. Since the punched materials are processed all the way to the final form, there isn’t much waste, and we save a lot on the costs of raw materials. To add, there is no heat treatment like in forging, so we save on electricity as well.

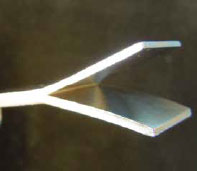

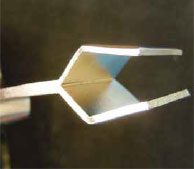

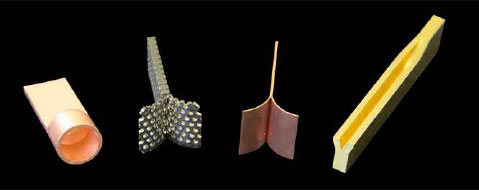

Sheet copper 3mm thick, split by the Warisaki Processing.

Can you believe it? This technology isn’t cutting, but is tearing through metal forming.

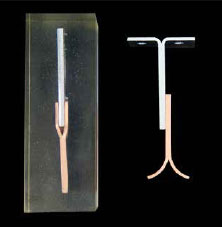

The process of splitting metal by WARISAKI method Left : Splitting Technology Below : Stamping Technology

What other uses are there?

President Seki: Warisaki is also useful when connecting various metal plates. For example, we can utilize the method to create the body of a vehicle using thin steel plates. The conventional approach is for the surfaces of both materials to be connected and secured through the use of welds or screws. When using

currently receiving many inquiries from various fields such as for light electric appliances, heavy electric machinery, medical, aviation and space, optical, electronics and more.

Could you please tell us the application of the Warisaki Method in relation to mass production?

President Seki: One of the major advantages of incorporating Warisaki into the production process is the increase in mass productivity and the stabilization of Warisaki, the edge of the main material can be split into a Y-shape so that the second material can be inserted and connected by calking. Through this, the connecting surface doubles thereby dramatically increasing the strength of the joint.

Also, the cores of the main material and added materials align, resulting in structural improvements. Connecting different metals is not only useful in the automotive field, but can also be applied to electric circuits. The method has also been applied to construction materials that require strength. We are quality. When processing a complex 3-dimensional product with a unified body, what was considered difficult through the use of progressive dies in metal presses now became possible in producing a final product from punched materials in a single step. Even connecting various metals, a process that fluctuates in quality dependent on the craftsman, can be mass produced in a stable fashion.

The Warisaki Potential

Could you speak a bit on your current endeavors?

President Seki: We are working on applying the Warisaki Method to challenging materials such as high tensile strength steel sheets and titanium. We have succeeded in splitting sheets with a thickness of 0.8mm in mass production, and we are currently working on the challenge of splitting sheets with a thickness of 0.1mm. This is technology that has only recently been developed, so there may be some demand for it in areas that we have yet to consider. We are currently in the process of developing applications by actually trying things out in response to inquiries from clients asking whether we can technologically fulfill their needs.

The Warisaki Potential

President Seki: Judging from comments made by businesses we work with, my prediction is that the trend will be for the cost cutting and lightening of products in various industries. At the current stage in technology, it is very challenging to make further improvements. We feel that the Warisaki Method will be useful in addressing the challenging demands of these various markets through its application to producing cut products, complex shaped products, sheet welding products through pressing, as well as connecting heavy current circuits. It is a technology with no precedent, so we feel that it will be useful in many fields.

Recovering From Tragedy

Can you speak about your company’s history and strengths?

President Seki: Our Company was established in 1950 as a manufacturer specializing in precision presses. We are unique, in that we have our in-house die development department, and, having a strong connection with the automotive industry, our achievements include providing products to all major automobile and electronics companies. We also provide pressed products for construction equipment, OA equipment, medical equipment, and light electrical equipment. Our Company’s foundation is our technology which was nurtured through answering to the expectations of quality for Japanese automobile companies, known for being the strictest in the world.

Could you tell us about your path to development?

President Seki: Our approach was quite influenced by the Great East Japan Earthquake. Many factories took heavy damage, and production came to a temporary halt. Our plant was back in order after a few weeks, but since our clients had already secured different suppliers, we had a hard time trying to reclaim our pre-earthquake sales volume. This was a very challenging time for our company. Aftershocks were still frequent at the time, so our clients started dealing with two companies in order to reduce risks. This wasn’t a situation we could break out of easily so we started looking for ways to make ourselves indispensable to our clients.

So this led to developing a technology that no other company possessed?

President Seki: Exactly. We felt the necessity for an original technology that only we could provide, and that opened our path to where we are now. At the time, other plants were attempting to wait out the aftermath of the earthquake. In order to develop our new technology, we switched our strategy to investing in equipment, and started incorporating new machinery while renovating the factory. Apparently this created some attention, and rumors about our strange actions in such trying times spread about. At the time, I was doing exactly the opposite of what everyone else was doing, but with the tangible achievements, I gained confidence as a proprietor on the actions I have taken.

President Seki: Exactly. We felt the necessity for an original technology that only we could provide, and that opened our path to where we are now. At the time, other plants were attempting to wait out the aftermath of the earthquake. In order to develop our new technology, we switched our strategy to investing in equipment, and started incorporating new machinery while renovating the factory. Apparently this created some attention, and rumors about our strange actions in such trying times spread about. At the time, I was doing exactly the opposite of what everyone else was doing, but with the tangible achievements, I gained confidence as a proprietor on the actions I have taken.

What was the inspiration behind the Warisaki concept?

President Seki: Right after the earthquake in March of 2011, I was staring at a piece of metal that I had brought home from work. My five-year- old son came to me and said, “Dad, wouldn’t it be great if metal could be split like cheese?” (String cheese that can be tom in a fibrous way is popular in Japan.) While doubting this in my mind, I replied, “That would be great.” I thought about this image of being able to split and tear metal, and how interesting it would be if this became a reality. Mentally prepared for being laughed at, I discussed this with my technicians. To my surprise, they were excited about the possibility, and this is how we started to develop this technology. Apparently it was unheard of for a rural press company to obtain a patent for a proprietary technology only after two years of development, so we were even visited by a representative from the patent office to see us.

Warisaki’s Rise To The World

I hear that there are already some new endeavors?

President Seki: My philosophy is, “There is no future without technology.” We have some developments using Warisaki as a basis, and it is approaching a level where we can bring it to the public.

Also, we are aiming at expanding our Warisaki concept internationally, and have been working towards globalization of this method at a fast pace. We have set up offices in Taiwan and Vietnam. In Vietnam, we have established our new production base, Seki Press Vietnam (SPCV) near Hanoi. We would like to utilize this location as our base to bring Warisaki to the world. In order to conduct business internationally, we are actively hiring technicians fluent in English and Chinese.

Lastly, could you say a few words to clients considering doing business with you in the future?

President Seki: Warisaki is a technology that has never existed anywhere in the world, and therefore, the applications that we can suggest are only a fraction of the possibilities available. We believe that Warisaki will be useful in all types of industrial areas around the world. We would like to invite those interested to actively inquire about the possible applications of our technology to your ideas. We consider it our mission to create something that the world has never seen before through collaboratively facing new challenges with clients. This state of the art technology Warisaki holds infinite possibilities. So, I would like to ask, “With Warisaki, how can we help you?”

Seki Press Co. Ltd.

Headquarters address: 4-3-20, Chikoku-cho Hitachi-city, Ibaraki, 316-0013 Japan

President and CEO : Masakatsu Seki

Primary Business : Various die design and manufacturing, Transfer – Progressive Single Press, Welding, Parts Assembly Process Established : 1950

Number of Employees : 85

Capital : 42,000,000 JPY

Quality Standard : ISO9001

Die Fabrication Plant: 2-36-21, Kujicho, Hitachi-shi, Ibaraki

Hitachiota Plant Address: 1495 Waku-cho, Hitachiota-shi, Ibaraki

Vietnam(Hanoi)Office: 2A, S1K5, 11XUAN DIEU, QUANGAN, TAYHO, HANOI, VIETNAM

Taiwan Office: 2F NO.75, Wenhwa 1st. RD., Lohshan Vill, Kueishan, Taiyuan County, 333, Taiwan,

R.O.C Company Name: Seki Press Vietnam (SPCV) : Dinh Tram Industrial Park Dong Van, Viet Yen District, Bac Giang Province, Vietnam Capital : 1,000,000 USD

Website : www.sekipress.jp/en