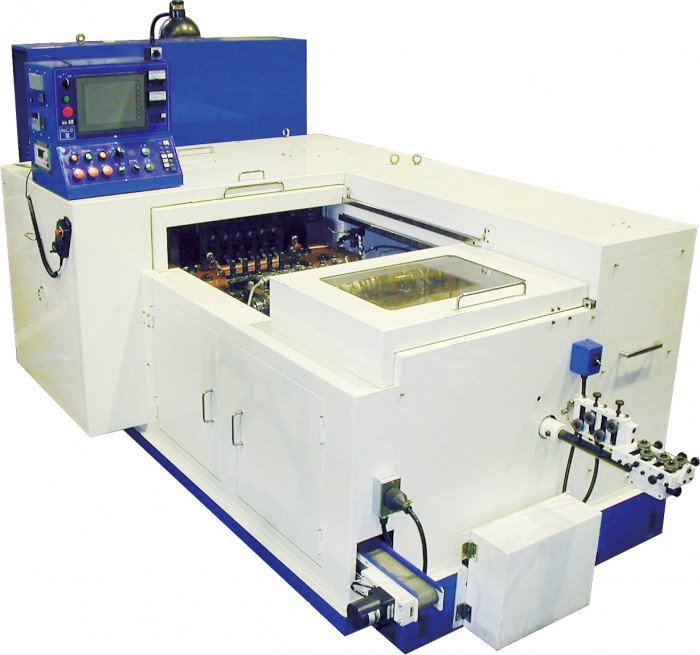

Design, Manufacturing of cold/warm forge press machines for screws and bolts

Nakashimada Engineering Works, Ltd. View Company Info

Nakashimada Engineering Works create press machines called headers and formers used to manufacture metal parts such as screws. Notable is that in relation to headers producing parts sized under 2.5mm, the company holds 80% of the shares in Japan, and 50% of the shares in the world.There are a few reasons that headers by Nakashimada Engineering Works accounts for majority shares throughout the world, but the Headers and parts formers of the Nakashimada brand are formed utilizing their proprietary technologies, and among them, the Fingerless Transfer and Die Slide are two notables that make the name “Nakashimada” renowned worldwide.

A Factory Capable of Creating The Worlds Finest and Most Precise Parts for a Century

Kurume City of Fukuoka Prefecture: Home to Hisashige Tanaka; known as the “Edison of the East” who founded what would later become a company which we all can relate to, Toshiba. Here in this prefecture is Nakashimada Engineering Works, located in Hirokawa of the Yame district neighboring Kurume. They create press machines called headers and formers used to manufacture metal parts such as screws. Notable is that in relation to headers producing parts sized under 2.5mm, the company holds 80% of the shares in Japan, and 50% of the shares in the world.

Kurume City of Fukuoka Prefecture: Home to Hisashige Tanaka; known as the “Edison of the East” who founded what would later become a company which we all can relate to, Toshiba. Here in this prefecture is Nakashimada Engineering Works, located in Hirokawa of the Yame district neighboring Kurume. They create press machines called headers and formers used to manufacture metal parts such as screws. Notable is that in relation to headers producing parts sized under 2.5mm, the company holds 80% of the shares in Japan, and 50% of the shares in the world.

The Standout Duo

There are a few reasons that headers by Nakashimada Engineering Works accounts for majority shares throughout the world, but the Headers and parts formers of the  Nakashimada brand are formed utilizing their proprietary technologies, and among them, the Fingerless Transfer and Die Slide are two notables that make the name “Nakashimada” renowned worldwide.

Nakashimada brand are formed utilizing their proprietary technologies, and among them, the Fingerless Transfer and Die Slide are two notables that make the name “Nakashimada” renowned worldwide.

“With multi-function presses within headers and formers, sending products to the next manufacturing process requires the use of fingers to move the objects. However, with Fingerless Transfer, the blank itself is sent to the next process without using fingers. This reduces the slight shifts and turns in the materials, dramatically improving precision while making it possible to do more processing within the same step.

The technology here then further evolved into the Die Slide technology. With this technology, it became possible to produce high-precision, extremely small and thin parts, even thinner than 2mm, which cannot be created with any conventional processes.

Mr. Hisatoshi Fuchikami elaborated further on their patented Pulse Dial technology which became a benchmark for many other makers. “Usually when configuring a press machine, one has to move the machine by hand while inputting the movements. This requires manipulating a heavy handle little by little, but instead, our company’s Pulse Dial will mechanically rotate the handle through the use of regenerative resistance. It is similar to the technology used in power steering for cars.”

Mr. Hisatoshi Fuchikami elaborated further on their patented Pulse Dial technology which became a benchmark for many other makers. “Usually when configuring a press machine, one has to move the machine by hand while inputting the movements. This requires manipulating a heavy handle little by little, but instead, our company’s Pulse Dial will mechanically rotate the handle through the use of regenerative resistance. It is similar to the technology used in power steering for cars.”

With this technology, such a machine can be single handedly operated with ease by a single person, and brings improved work efficiency with the reduction in the operator’s workload.

Such quality and precision has caught the eyes of many and now Nakashimada Engineering Works is involved with developing space related products as well.

“In order to prevent satellites that have finished their roles from becoming space debris, there is a method of having it break into the atmosphere to smolder harmlessly. We collaborated with Tohoku University to develop this method which incorporates a unit that attaches a thin parachute onto satellites in order to reduce the speed of their fall, guaranteeing that they are led to burn out of existence in the atmosphere.”

This satellite unit is already in use, and has already been delivered to Germany’s Universitat Stuttgart’s research facility. In addition, Tohoku University will also be receiving this unit in February of this year. As space related businesses develop and the issue of space debris becomes more common, the units created will sure to be something of interest in the future.

No Copies, All Quality

Developers at Nakashimada Engineering Works operate under a philosophy passed down since the company’s establishment. The philosophy is to never copy.

“Instead of wasting time figuring out how to copy something, the time should be put to better use thinking of new ways to create better products. If you copy, you can never surpass the products you are copying.”

There is an interesting story from when Nakashimada Engineering Works was first founded. A client brought from outside of Japan a header, and asked for the exact same to be made. Upon receiving the request, the president at the time declared that he would create one that would surpass what was brought. This company motto of not copying that has been passed down since its establishment is Nakashimada Engineering Works’ declaration of continuing its standard of producing only quality products.

In recent years, copies of products such as the Pulse Dial that Nakashimada Engineering Works created have started to appear.

“We are obviously not pleased by this, but it is what it is, and we will treat it as such. On the other hand, I believe this also means that out technologies and techniques are that refined to be benchmarks for others to look upon.”

In reality, there have been a few cases where users have switched from Nakashimada products to cheaper copies. However, in the end they switch back to Nakashimada products. While machines and mechanisms can be copied, the quality of products and the stability of production can’t be replicated.

Our Customers are our Mission

Nakashimada Engineering Works operates with the mission of fulfilling the clients’ requests 100%. Because they continue to face different demands from different clients, most of the machinery the company produces is custom made.

Nakashimada Engineering Works operates with the mission of fulfilling the clients’ requests 100%. Because they continue to face different demands from different clients, most of the machinery the company produces is custom made.

“While we do have a product catalog, we have never sold a product exactly as it is listed. In order to honor the needs of our clients, we always have some aspects that are customized to our client’s requests.”

Staying true to the customer oriented operations of manufacturing and selling machinery that reflect the clients’ needs 100% requires the creativity and technology to create something that has never existed before, from scratch.

something that has never existed before, from scratch.

“Our designers do not perceive things in terms of whether it’s possible or not, but rather push forward by seeing things as something that needs to be realized. Pushing forward is the pre-requisite for new products. When you have a collective of designers and plant workers with this attitude, working and thinking together, unexpected ideas start to inexplicably appear. The environment of designers and manufacturers always working at their best is the reason for the high quality of our products.”

Ideas manifested from the accumulation of communication between design staff and the onsite workers tend to yield many parts with shapes and forms that have never been seen before.

“70% of the parts used in our headers and formers, from jigs and more, are created in-house. As a result, we make each part we produce as precise as possible, which improves the precision of the machine comprised of over 1000 parts. We believe that our headers and formers are of such high quality because of the fact that we manufacture a majority of the parts needed ourselves.”

“70% of the parts used in our headers and formers, from jigs and more, are created in-house. As a result, we make each part we produce as precise as possible, which improves the precision of the machine comprised of over 1000 parts. We believe that our headers and formers are of such high quality because of the fact that we manufacture a majority of the parts needed ourselves.”

The work environment and creating the majority of parts in-house are all due to the shared concept within the company of, not just creating a machine, but creating one that can create the parts the client is seeking.

A record, carved out over a century.

Continuation: When the Ordinary Becomes Extraordinary

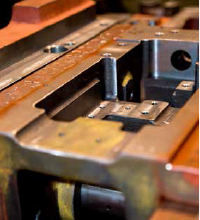

The source of precision and quality of Nakashimada Engineering Works comes from a special hand-scraping technique. This technique lowers the frictional resistance of sliding metal surfaces, and is used in the finishing stages of manufacturing, creating microscopic dents.

“Quality and high precision of a machine is derived by humans. Due to the extensive amount of experience needed to be gained, those possessing hand-scraping techniques are in a decline. However, most of the workers in our plant have acquired this technique. This technique is absolutely essential to the production process of our headers and formers.”

Machines treated with this hand-scraping can operate for decades without the sliding surfaces deteriorating, giving the machines long lasting life. This technique, which is now a unique strength of this company, wasn’t honed just to be a feature to be boasted of.

Machines treated with this hand-scraping can operate for decades without the sliding surfaces deteriorating, giving the machines long lasting life. This technique, which is now a unique strength of this company, wasn’t honed just to be a feature to be boasted of.

“This technique was used by every manufacturer in the past, but in order to cut costs, and because of the challenges of passing down this skill, hand-scraping has started to disappear. For us, a company that pursues quality, hand scraping is not special, and not out of the ordinary. Little by little, we perform our ordinary tasks with the attention it deserves. We pass on our techniques through everyday work.”

Another example of how daily operations have evolved into a strength that no rivals can match is the company’s superior customer support. The plans for every header or former developed or manufactured by the company have been tightly guarded in a safe. No matter how old the machine, maintenance is possible.

“We treat our plans as treasure. Because we have the design drawings, we can provide 100% of the replacement parts. Even products that have gone through resale can be identified using the serial number. Recently we had a request to change some parts on a machine that was over 50 years old. Maintenance was done, and of course, the machine is still running today.”

Quality is Universal

Nakashimada headers and formers of high precision and quality are present in manufacturers of all fields.

“Our machines are used for cars, planes, architecture, electronics, IT, cell phones, watches, and more. Our machines are even used to create the tips of ballpoint pens, decorations, medical equipment, fashion, and to process a variety of metal materials. Recently we have been getting more orders for headers and formers that process materials in challenging and complex ways.“

“Our machines are used for cars, planes, architecture, electronics, IT, cell phones, watches, and more. Our machines are even used to create the tips of ballpoint pens, decorations, medical equipment, fashion, and to process a variety of metal materials. Recently we have been getting more orders for headers and formers that process materials in challenging and complex ways.“

Mr. Fuchikami states that taking manufacturing one step at a time with seriousness is what brings about quality and technical development. He says the most significant asset of Nakashimada Engineering Works is the managerial philosophy prioritizing new challenges over immediate profits.

“We do not plan on stopping our domestic production. We would like to spread our products worldwide while staying true to the concept of ‘Made in Japan.’ High quality and high precision is a need that is universal regardless of time or location.”

Nakashimada Engineering Works, Ltd.

Business Description : Design and manufacturing of cold/warm forge press machines for screws and bolts

Headquarters Address : 1164-4 Hiyoshi Hirokawa Yame,Fukuoka, 834-0196 Japan

CEO : Masanori Nakashimada

Established : 1951

Founded 1911

Number of Employees: 127

Website: www.nakashimada.co.jp