From infrastructure, to semiconductors, nuclear, medical care, to the space industry, there is an increasing demand for jointing products made from metals and ceramics. Kawaso Texcel Co. Ltd., with its advanced technological capabilities with regard to strong, air-tight jointing of metal-on-metal and metal-on-ceramic, has an excellent reputation as one of Japan’s leading specialist manufacturers of air-lock strips using a wide variety of metals and ceramics materials.

Companies

Kinsei Engineering Inc, is a long-established cast metal manufacturer founded in 1986. They are known as the original developer and seller of the V-Pulley. The strength of the company is its in-house integrated production system, using its wealth of knowledge and experience to design and develop metal casting using 3D CAD / CAM / CAE, and to manufacture and assemble precision machinery. The company knows its raw materials very well only a casting manufacturer can do, and this distinctive position enables the company to propose solutions and services that can help its customers eliminate waste between each step of the production process. Through the ingenuity of its employees, Kinsei’s production […]

Almost 30 years ago, Kashima Bearings Corporation began manufacturing their plastic ball bearings. When the founder Shizuo Kashima visited his wife’s hometown, someone at the fishing port complained to him that the conveyor belt that carries fish would always get rusty. So, he suggested using parts made of plastic resin that is resistant to alkaline from fish and corrosion by salt water. And then, he designed his own plastic ball bearing and started manufacturing it.

ATOM Co., Ltd. is a company specializing in factory automation, and has vast experience in the automation of the production of various industrial goods. Yasutaka Ichinose, President of the company, is confident that anything from combining the ingredients of snacks to the packaging of contact lenses can be automated. “There is no such thing as production that can’t be automated,” says Mr. Ichinose. Armed with their know-how of an integrated approach to industrial equipment encompassing everything from design to installing, the high level of technology and quality Japan is known for, and detailed customer support, the company has been receiving an increasing amount of orders from overseas and has developed […]

Maruoka Kogyo is Japan’s proudest maker of high-quality wooden canvas frames. By passing the old-age Japanese tradition of wood processing to the current generation and using the finest materials, the company has been making wooden canvas frames for years and its products are widely used by various famous painters and art museums in Japan. The combination of carefully-selected quality materials, skilled craftsmanship and the high precision of their manufacturing machines gave birth to a wooden canvas frame that can hold paintings even a century has passed.

Ito Bindery is a bookbindery of long standing. Utilizing their book binding techniques nurtured through the years of cutting thickly stacked paper without a millimeter of error, the company has developed high-quality memo blocks and drawing pads. The backing, created by recycled cardboard gives the pads stability, has a unique design which is the height of simplicity. The craft pads using craft paper that doesn’t whiten has a distinctive texture which is close to the pulp it is made from. These memo pads and drawing pads are loved in Europe, as well as by people who are interested in fashionable lifestyle items.

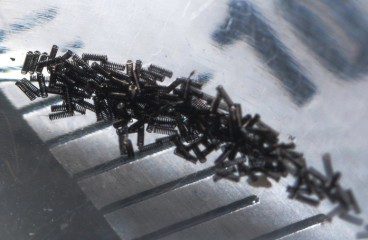

Satte-spring developed the smallest type of spring in the world. It has a measurement of only 14μ in wire diameter and 80μ in external diameter, and even a five hundred of them can occupy a single square inch of space. Only a handful of major manufacturers in Japan today were able to develop microscopic springs that are barely visible to the naked eye, yet Satte-spring, which is only composed of twenty employees, made a significant and unprecedented technological success in the springs’ development. The company has an on-site simple space dedicated for research activities and it is occupied by young engineers who went after developing the world’s smallest spring that […]

The year 2011 marked the birth of a large electric motorcycle that, through its fresh and sharp design, gives you a look into the near future. Its name is zec00. With the motif of flowing curves, the vehicle thoroughly pursues the aesthetic of “cool,” with its mainframe machined out of aluminum, single-sided swing-arms supporting the wheels, and cowl made of carbon. At the same time, as a motorcycle the zec00 is no child’s toy; it can go up to 200 km/hr.