MURAMASA: the Japanese sword (katana) that is famous for its highest quality. Today, that extraordinary sword is reborn in the mold used in the preparation of medicine. Nanno Co., Ltd., a company that designs and manufactures metal molds, has developed a tableting mold called “Muramasa” for compressing and molding powder that becomes medicine tablets. The “MURAMASA” mold has the durability that surpasses conventional products found in the market, and so it has attracted a great deal of attention in the pharmaceutical industry.

Companies

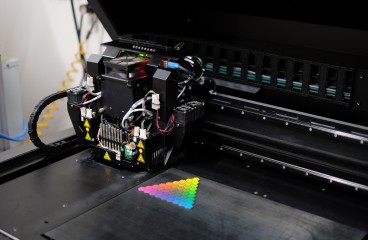

Swany Co., Ltd., is a company that makes excellent use of modeling technology in making product designs and prototypes with the use of the latest 3D printers and 3D CAD to offer consistent support of mass production. The company speedily converts the ideas of customers into data, and produces a prototype using a 3D printer. Thus, this greatly reduces the time for product development. Also, because the company can quickly deliver 3D data, it can even respond to extreme customer requests; even only with a two-dimensional drawing, or sketch, the company can “meet you in the morning, and then deliver a prototype in the evening.” The company has attracted attention […]

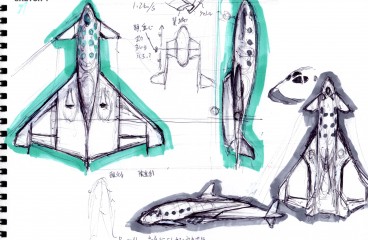

Low-cost and safe access to Space with an Engine that Switches between Jet and Rocket Modes! There is a small Japanese start-up company attempting to develop a spacecraft with a few engineers in a small garage. PD Aerospace, Ltd. is aspiring to pioneer the space business with proprietary technology that combines “jet combustion” and “rocket combustion” into a single engine, which has been conventionally seen as incompatible.

Gamagori Seisakusho is a manufacturer of components of precision machinery. The company’s motto is high-mix, low-volume production, and while the company has only 13 people, it has been involved and continues working on requests from a number of research institutes such as the National Institute for Molecular Science (Japan) to manufacture its experimental devices and to produce parts for artificial satellites. The company’s greatest strength is in the finishing of easily-distorted cut materials, such as lamination of products with complex shapes with a high degree of precision, and can perform processing up to ±3~5 microns. The company’s precise metal processing technology, combined with the capability to provide the best solution […]

This is what you’ll be telling your friends if you order from Comlux Co., Ltd., a door manufacturer located in Hida Takayama, A.K.A. “woodworkers’ village.” Hida has a long history of producing masterful woodworkers, and this company carries on the local woodworking tradition, crafting premium custom doors using natural wood and paint. The high quality handcrafted doors have a feel to them that appeals to many people in Japan, and these doors are installed in many homes.

Plus / minus 1mm. That’s the level of precision Shimano’s belt conveyors are expected to operate at for an automated production line of an automotive manufacturer. Their conveyor belts are not just a delivery system that connects production units, they quickly transport the processed products from one unit to the next, delivering them to the exact location in a highly precise manner. Because of the high precision, they are often used alongside industrial robots. Some of their fastest belts clock in at 120m per minute, which are great for large-scale factories overseas.

“HITORISHIZUKA” developed by Shizuka Inc. is a completely new soundproofing material used for the prevention of industrial/machinery noise. It cuts the noise with a thin and light material and absorbs the noise with a hard material. “HITORISHIZUKA” overturned the conventional wisdom that thick and heavy materials are for cutting the noise and soft materials are for absorbing the noise. Moreover, it covers low-frequency noise unable to insulate with common soundproofing materials and is easily processed according to the sound source. This unique soundproofing panel is now gathering lots of attention from domestic factory makers and highways to construction sites as a noise countermeasure.

San-ei Seisakusho Co., Ltd. provides every single piece of equipment and machinery that suits the needs of its customers. Since its inception, the company has been engaged in the manufacturing of machine parts in a broad range of industries such as the automotive, powder and sanitary products industry, and in the processing of medical equipment parts. Rather than the mass-produced standardized products such as bearings and shaft that are readily-available, San-ei Seisakusho is a specialist at manufacturing complex, small batch/single item, customized products. Normally, parts with complex shapes are produced by a 5-axis control finishing machine, however the company can make 2.5 dimensional fabrication of lathes and machining centers by […]